► Tech information form of Flat Enamelled Aluminium Wire:

Thermal class: B(130°C), F(155°C), H(180°C), H(+200°C), C(220°C), C+(240°C)

Rectangular size: A: 1mm-10mm b: 3mm-16mm

Product standard: IEC/NEMA/JIS/GB

Applications: compressor motors, air-conditioning motors, washing machine motor, explosion-proof motors, the motor windings sealed

Delivery time: 10 days-30days

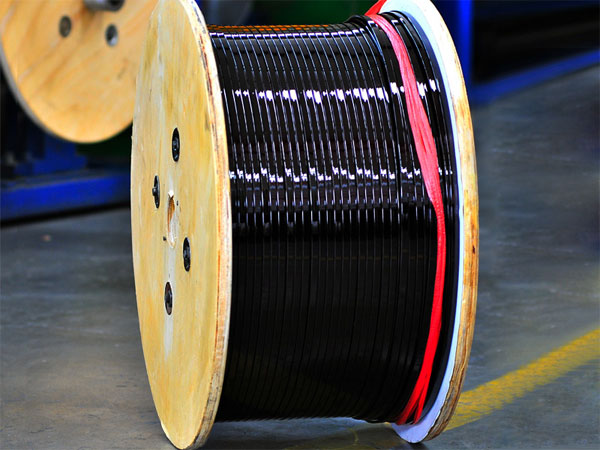

Package: wooden spool or as your requirement

Price term: FOB/CIF/CNF/DDU/DDP

► Usage of Flat Enamelled Aluminium Wire:

Enameled Aluminum Winding Wire is used in manufacturing ARC welding machines. it is applicable to all types of large and medium-sized electrical machinery, transformer , generator, electrical motor windings, exhaust fan, Air-conditioner, washing-machine, compressor, deflection yoke etc.

► Product types of Flat Enamelled Aluminium Wire:

1. Thermal class:130, 155, 180, 200, 220 degree

1) Polyester enameled aluminum wire, class 130

2) Modified polyester enameled aluminum wire, class 155

3) Polyesterimide enameled aluminum wire, class 180

4) Polyester (imide) coated with polyamide-imide enameled aluminum wire, class 200

5) Polyimide enameled aluminum wire, class 220

► The advantages of Flat Enamelled Aluminium Wire

a. Compared with the copper enameled wire, enameled aluminum wire is easier to winding, also there is a solid oxide film on the surface of enameled aluminum wire, which make it has a good insulating effect, a long life.

b. Due to the good insulating effect of aluminum film layer, its heat-resistant temperature can be 20 degrees higher than the copper wire;

c. The greatest benefit of using aluminum is that it is 1 / 3 lighter than copper which significantly lower the production costs, second it can attach to the solids easily, and third it can also reduce the freight and transportation during the operation.

Chinese

Chinese English

English Franch

Franch Tel:0086-371-65861282

Tel:0086-371-65861282  Email:office@cnlpzz.com

Email:office@cnlpzz.com

(Live chat)

(Live chat)